Agricultural IoT system sends power through the soil

This article is part of our exclusive IEEE Journal Watch series in partnership with IEEE Xplore.

How do you supply power to agricultural Internet of Things (IoT) sensors that are scattered all over the landscape?

Power is a major obstacle on the path to real-world smart agriculture. Even the most energy-efficient devices still need power to track and report GPS coordinates, moisture levels, temperatures, soil acidity, nutrient concentrations, and invading pests. And there are as many solutions as there are data to track: long-life batteries, solar panels, wind generators, laser and microwave energy beams, and even capacitor-laden drones that can settle over and charge buried induction coils.

Now researchers at Tennessee Technological University, in Cookeville, have another new idea: sending electric power directly through the soil. This isn’t just a laboratory curiosity—the researchers have transmitted electric power using a through-the-soil (TTS) system to power remote sensors and long-range, low-power LoRa radios distributed over a 2-acre test plot through multiple growing seasons.

The engineers powered their tests with a mobile solar panel array, and required roughly 0.1 kilowatt-hour per day. If they had paid retail rates for that power, it would have cost them just over a penny per day.

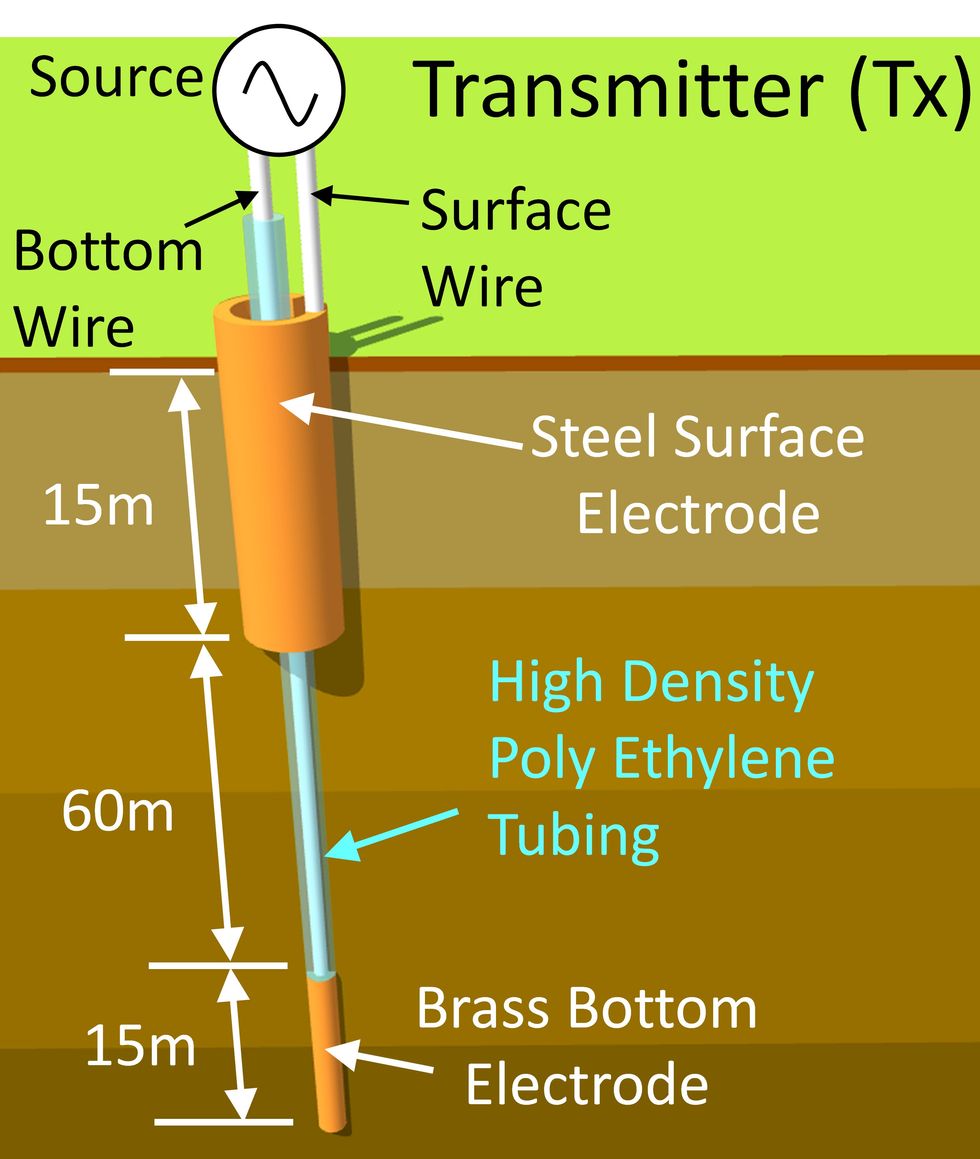

The TTS transmitter is a pair of electrodes, one on the surface and one sunk 90 meters underground.Tennessee Tech University

The TTS transmitter is a pair of electrodes, one on the surface and one sunk 90 meters underground.Tennessee Tech University

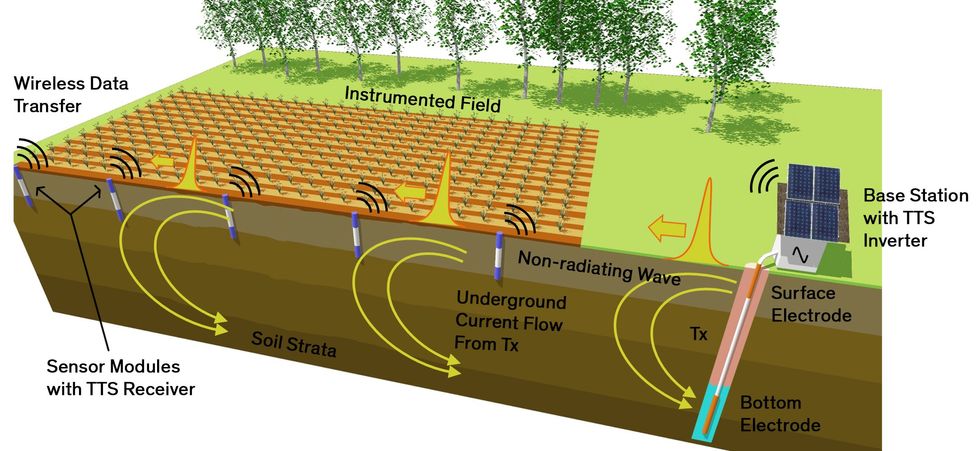

The researchers’ TTS system has three main components: a power transmitter, one or more power receivers, and multiple sensor modules.

The group’s 2-acre test network linked four sensor packs. Each included a Microchip microcontroller, a LoRa network integrated circuit, a 1-millifarad capacitor that stored power for transmission bursts, and two soil sensors—one for moisture and one for temperature. Combined, the trial’s four sensor modules required 0.8 watts.

The TTS system’s transmitter, however, drew more power. A series of improvements lowered input-current demand from 500 W to 250 W. And because the system did not need to monitor sensor readings continuously, a duty cycle consisted of 1 minute on and 59 minutes off, which brought daily power consumption down to 0.1 kWh.

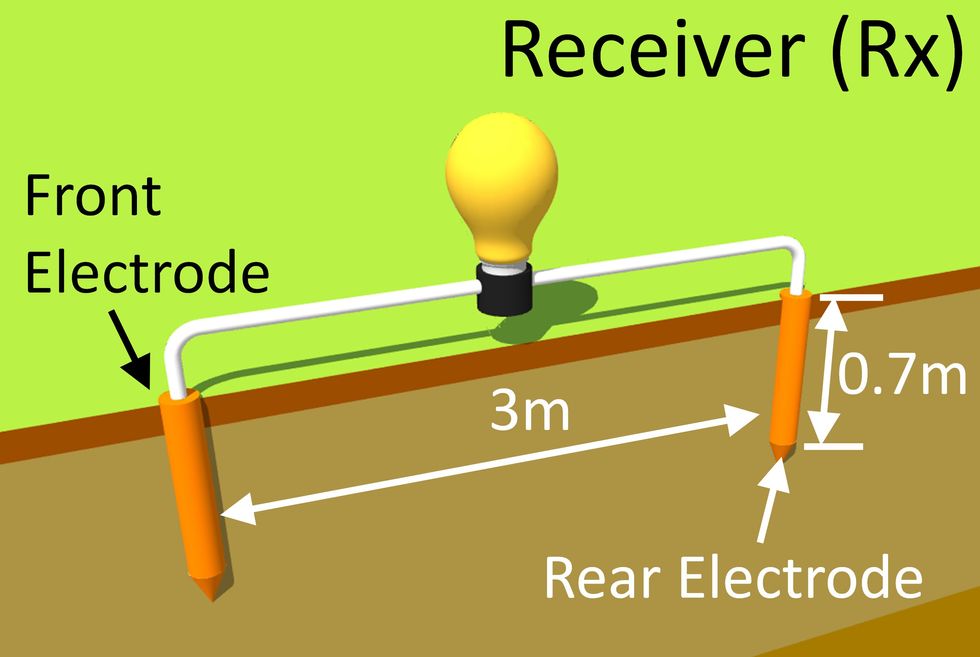

The TTS receiver has two 0.7-meter electrodes spaced 3 meters apart to pick up current from the transmitter.Tennessee Tech University

The TTS receiver has two 0.7-meter electrodes spaced 3 meters apart to pick up current from the transmitter.Tennessee Tech University

Conceptually, the transmitter and multiple receivers form coupled circuits. Power goes deep into the ground at the transmitter, and receivers out in the fields draw it up as needed. “The geometry of the TTS system is similar to a water well, offering a possible way to integrate this [long-range wireless power transfer] technique into existing farming infrastructure at very little cost to the user,” the researchers wrote in a paper published in the February 2024 issue of IEEE Transactions on Industrial Electronics.

The transmitter consists of a surface electrode and a bottom electrode. The surface electrode is a 15-meter-long steel well casing sunk into the top soil layers. The bottom electrode threads through the casing to stretch 90 meters underground, with 75 meters of heavy-gauge wire in a high-density polyethylene tube connected to another 15 meters of exposed brass.

At each receiver are two 0.7-meter-long rods driven into the ground 1 to 3 meters apart. The sensor module is wired between these electrodes. Voltage depends on the distance from transmitter to receiver and the spacing between the receiver electrodes. Operators can adjust receiver-electrode spacing to deliver the voltage they need (in this case, 3.6 volts) to run the sensor module.

Charles Van Neste, an assistant professor at Tennessee Technological University, and his colleagues started working on TTS power in 2016. Since then, they’ve studied the electrical properties of soil and learned how current behaves underground, while also making efforts to expand the system over larger plots of land.

During their work, the researchers learned that while soil is generally an unreliable conductor, agricultural soil—which is irrigated and regularly provided with ions through fertilizer—has much better electrical conductivity. They’ve also found that current follows soil layers; in other words, current tends to travel horizontally across a particular stratum of soil. This discovery informed the transmitter’s vertical design, which allows the current to find the best stratum to move through. And they’ve discovered that TTS works best at very low alternating-current frequencies, specifically below 50 kilohertz.

The TTS system uses underground transmitters and receivers to create a current directly through the soil.Tennessee Tech University

The TTS system uses underground transmitters and receivers to create a current directly through the soil.Tennessee Tech University

The 2-acre test network transmitted power at 60 hertz. Transmission efficiency fell off as the receivers moved farther from the transmitter. “The model shows that improvements can be made by lower contact resistance but also in running at higher frequencies, and this is a major focus of our research at the moment,” says Van Neste.

Tennessee Technological University has filed worldwide patents on TTS, and the researchers are working toward commercialization with a startup company, Terra Watts.

Van Neste says that TTS can achieve power transfer over “a fairly exciting distance.” He adds, “Better [transmitter/receiver] contacts are showing improved transfer efficiency. Our ideas have also started to evolve into ways of including data transfer in tandem with power, so that sensor systems can transmit their information completely underground. This would allow sensors to be fully buried, and is something we hope to demonstrate soon.”

“As long as nothing catastrophic occurs,” says Van Neste, “we are hoping to demonstrate power transfer over a 150- to 200-meter radius (about 30 acres) by the end of summer.” As part of that test, they plan to use a newly designed inverter that produces high-intensity current at low duty cycles. “We tested this new inverter last week and achieved the same current densities we got in the [Transactions on Industrial Electronics] paper, but at only 10 percent of full inverter operation. We are very excited to explore power transfer over greater areas,” he says.